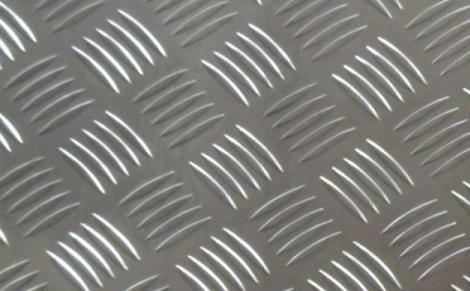

Methods for Choosing Anti-Slip Aluminum Plates

Release time:

2020-03-12

Anti-slip aluminum plates are generally purchased in 5052 rust-resistant and anti-slip aluminum plates.

Anti-slip aluminum plates are generally purchased in large quantities as 5052 rust-proof and anti-slip aluminum plates. So how do we select high-quality anti-slip aluminum plates? The use of anti-slip aluminum plates is very wide, and we often see them in our daily lives. Good anti-slip aluminum plates should be considered from aspects such as material composition, thickness, hardness, and oxidation film.

How to choose anti-slip aluminum plates

First, look at the materials. The aluminum profiles used in high-quality aluminum alloy anti-slip plates should meet national standards regarding thickness, strength, and oxidation film. The wall thickness should be above 1.2 mm, the tensile strength should reach 157 Newtons per square millimeter, the yield strength should reach 108 Newtons per square millimeter, and the thickness of the oxidation film should reach 10 microns. If these standards are not met, it is considered inferior aluminum alloy doors and windows and should not be used.

Second, look at the processing. High-quality aluminum alloy anti-slip plates are finely processed, with careful installation, good sealing performance, and smooth operation. Inferior aluminum alloy doors and windows blindly choose aluminum profile series and specifications, are poorly processed, use sawing instead of milling, do not install according to requirements, have poor sealing performance, and operate roughly. This not only leads to air and water leakage and glass shattering but also makes it easy for strong winds and external forces to knock off or damage the sliding parts or glass, causing property damage and injury.

Third, look at the price. Generally, high-quality aluminum alloy anti-slip plates have a higher manufacturing cost, making them about 30% more expensive than inferior aluminum alloy anti-slip plates. Currently, there are many individual businesses processing aluminum alloy anti-slip plates, and they do not understand the structural characteristics and performance of these plates. To reduce costs, they cut corners and use inferior materials, which poses significant risks and is generally not advisable. It is best to choose products from reputable manufacturers of aluminum alloy anti-slip plates.

Related Blog

What should manufacturing enterprises do in terms of environmental protection?

Manufacturing enterprises must balance economic benefits with environmental protection.

2025-01-11

The Importance and Strategies of After-Sales Service Guarantee

After-sales service is not only related to the current performance of the enterprise, but also an indispensable part of its long-term development and brand building.

2025-01-11

The official website is now live, bringing users a brand new experience.

Luoyang Huake Metal Co., Ltd. is pleased to announce that our brand new official website is now live!

2025-01-11

Ensuring product quality is crucial for enterprises!

Ensuring product quality is a crucial and indispensable core element for enterprises.

2025-01-11

Methods and Principles of Surface Treatment for Aluminum Materials

Discuss the shortcomings of three surface treatment methods for aluminum profiles: 1. Anodizing: The oxide film can easily mix with impurities and turn yellow; materials tend to stick together.

2020-03-12